During this lab, I worked with the IMU.

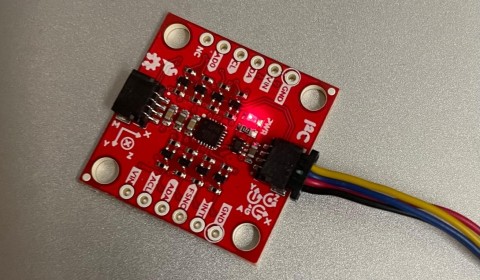

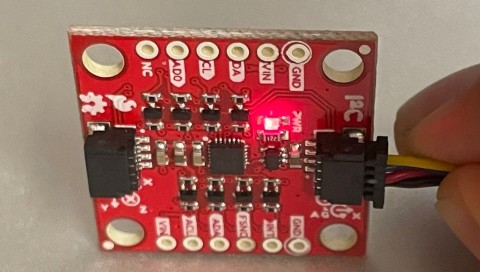

IMU Setup

Artemis Connections

I connected the SparkFun 9DOF IMU to the Artemis Nano via a QWIIC connector.

IMU Sanity Check

After installing the SparkFun 9DOF IMU Breakout_ICM 20948_Arduino Library via Arduino’s library manager, I ran the basic example to verify that the setup was working correctly. You should see something like below,

Scaled. Acc (mg) [ 00254.88, 00059.08, 00973.14 ], Gyr (DPS) [ -00001.78, -00000.51, -00001.42 ], Mag (uT) [ -00021.45, -00027.90, 00062.55 ], Tmp (C) [ 00034.21 ]

AD0_VAL

The AD0_VAL refers to the last bit of the I2C address of the IMU. It is by default set to 1 on the IMU, and thus ADO_VAL should be set to 1 to communicate. This value can be changed by closing the ADR jumper which sets it to 0. Also, the IMU seems to offer a AD0 pin which I think can be set by software when connected to a GPIO pin.

Understanding sensor values

Placing the IMU flat on a surface,

The accelerometer and gyro data should look something like

Scaled. Acc (mg) [ -00003.42, -00012.21, 01021.00 ], Gyr (DPS) [ -00001.12, 00001.79, 00000.08 ]

You can see that there is roughly 1g of acceleration due to gravity on the Z-axis.

Placing the IMU on its side as below, you should now see 1g on the y-axis.

The gyro measures the angular velocity of the IMU in degrees per second (DPS). Rotating it around the Z-axis, the angular velocity about the z-axis will increase.

Accelerometer

The accelerometer data can be used to compute the pitch and roll of the IMU via the following formulae, \(p = \text{atan2}(a_z, a_z), r = \text{atan2}(a_x, a_z)\)

Then,

I found that the accelerometer was fairly accurate within about 0.02 rad of the true answer. For 90 degrees pitch, I got 1.58 rad (the true value is 1.57). I got -1.56 for -90 degree pitch. For 90 and -90 roll, I got 1.56 and -1.56 respectively.

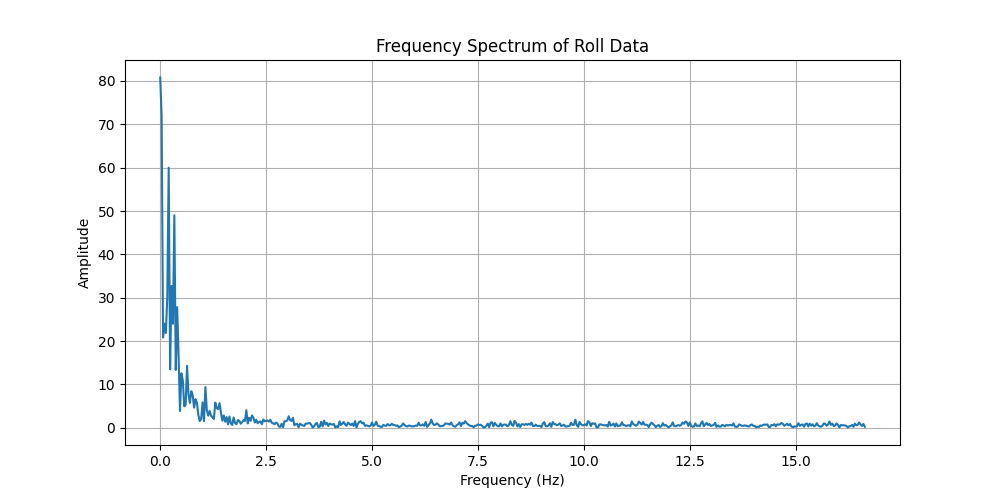

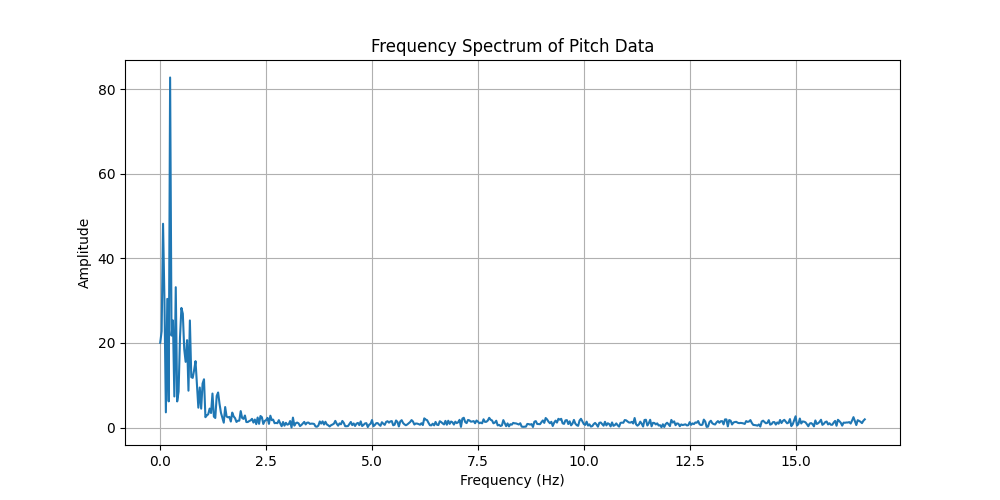

Noise in frequency spectrum

While the noise in my testing was fairly low, when running the RC car, there will be a lot of vibrational noise that will make readings noisy. To elimate this, I use a low pass filter.

Fourier Transform

To figure out which frequencies to keep, I obtained timestamped sensor readings from the IMU while I moved it around.

The graphs above show a peak around 0 Hz which is expected, and it shows that the pertinent signal has frequencies > 1.5 Hz. So, eliminating these frequencies should help combat sensor noise.

Low Pass Filter

Using a low pass filter, that’s defined by the following recursive relation, \(y' = \alpha * x + (1-\alpha) * y\) where \(x\) is the raw measurement, \(y\) is the previous filtered measurement and \(y'\) is the new one. Then, to eliminate frequencies greater than \(f_c = 1.5\), set \(\alpha = \frac{1}{1 + \frac{f_s}{2\pi f_c}}\) where \(f_c, f_s\) are the cutoff and sampling frequencies.

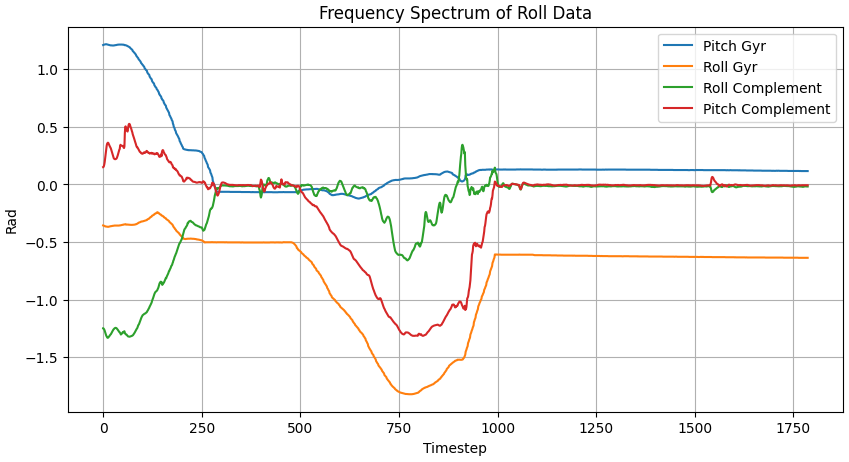

Gyroscope

I now use the Gyroscope to obtain roll, pitch and yaw data via dead reckoning. I use the following code for it,

float dt = (float) (times[c] - times[prev])/1000;

float dx = sensor->gyrX()*dt * DEGTORAD;

float dy = sensor->gyrY()*dt * DEGTORAD;

gyr_pitches[c] = gyr_pitches[prev] + dy;

gyr_rolls[c] = gyr_rolls[prev] + dx;

gyr_yaw[c] = gyr_yaw[prev] + sensor->gyrZ()*dt * DEGTORAD;

Using the gyro produces less noisy estimates, but since dead reckoning is used errors accumulate rapidly leading to bias. One can imagine using both measurements in combination to produce a more accurate and less noisy estimat.

Complementary filter

I used a complementary filter to try and get the best of both worlds with the two sensors. I found that the complementary filter was more noisy than just the gyroscopic estimates, but they were less biased.

The complementary filter is defined as follows,

The complementary filter is defined as follows,

acc_pitches[c] = lpf(acc_pitches[prev], pitch);

acc_rolls[c] = lpf(acc_rolls[prev], roll);

float dt = (float) (times[c] - times[prev])/1000;

float dx = sensor->gyrX()*dt * DEGTORAD;

float dy = sensor->gyrY()*dt * DEGTORAD;

gyr_pitches[c] = gyr_pitches[prev] + dy;

gyr_rolls[c] = gyr_rolls[prev] + dx;

gyr_yaw[c] = gyr_yaw[prev] + sensor->gyrZ()*dt * DEGTORAD;

comp_pitches[c] = (comp_pitches[prev] + dy)*(1-alpha) + alpha * acc_pitches[c];

comp_rolls[c] = (comp_rolls[prev] + dx)*(1-alpha) + alpha * acc_rolls[c];

Sample Data

Speed of Sampling

To improve the sampling speed, I removed all manual delays from the control loop, and every iteration checked whether the sensor data was ready, and if not I continued. During my testing I saw a sample rate of roughly a sample every 2.86 ms which is a rate of 372 samples per second. I created 7 float arrays that stored the filtered pitch, roll from the accelerometer, roll, pitch and yaw from gyro and roll, pitch for the complementary filter. I chose to use floats because the magnitude of the values is not very high, so float precision would suffice. I also had an unsigned int array for timestamps. With a length of 10000 each, it took about 320Kb of memory and can store ~26s of data.

Sending 5s of data over BLE

I used the following code to do this,

void get_data(ICM_20948_I2C *sensor)

{

times[cnt % ARR_SIZE] = millis();

float roll = atan2(sensor->accX(), sensor->accZ());

float pitch = atan2(sensor->accY(), sensor->accZ());

if (cnt > 0){

int c = cnt % ARR_SIZE;

int prev = (cnt - 1) % ARR_SIZE;

acc_pitches[c] = lpf(acc_pitches[prev], pitch);

acc_rolls[c] = lpf(acc_rolls[prev], roll);

float dt = (float) (times[c] - times[prev])/1000;

float dx = sensor->gyrX()*dt * DEGTORAD;

float dy = sensor->gyrY()*dt * DEGTORAD;

gyr_pitches[c] = gyr_pitches[prev] + dy;

gyr_rolls[c] = gyr_rolls[prev] + dx;

gyr_yaw[c] = gyr_yaw[prev] + sensor->gyrZ()*dt * DEGTORAD;

pitches[c] = (pitches[prev] + dy)*(1-alpha) + alpha * acc_pitches[c];

rolls[c] = (rolls[prev] + dx)*(1-alpha) + alpha * acc_rolls[c];

}

else{

acc_pitches[cnt] = pitch;

acc_rolls[cnt] = roll;

}

}

void loop()

{

// BLE.advertise();

BLEDevice central = BLE.central();

// If a central is connected to the peripheral

if (central) {

Serial.print("Connected to: ");

Serial.println(central.address());

// While central is connected

while (central.connected()) {

if (myICM.dataReady()){

myICM.getAGMT();

// read sensor data

get_data(&myICM);

}

// Read data

read_data();

cnt++;

}

Serial.println("Disconnected");

}

}

Stunt

I found the motors had very high torque which allowed the robot flip if you change direction suddenly. The video below demonstrates this

Overall, I learnt a lot about how to combat a lot of the issues like noise and error compounding when using sensors in real life. It was cool to see how well simple exponential moving averages are at smoothing out a signal.